Continuous pulsating extractors

Ingehim offers our own in-house continuous pulsating extractors (CPE). CPE belongs to a new class of heat and mass transfer equipment and it represents the only promising alternative to such extractors as macerators, percolators and screw extractors. CPE is intended to produce extracts from raw materials of plant, animal, mineral or man-made origin in the system “liquid extractant–solid phase raw material”. The recommended areas for the CPE application include food, pharmaceutical, cosmetic, chemical, oil refining, metallurgical and other industries. In some industries, the extraction process may be also called by other names depending on the industry. For example, the process may be called “diffusion” in the sugar industry and “leaching” in the metallurgical and chemical industries.

The CPE work is based upon the original method of technological transportation of a solid dispersion (raw material) in countercurrent with a liquid extractant (solvent) inside a column apparatus without using any internal mechanical devices (Fig. 1). Raw materials continuously move inside the apparatus in the “piston” mode by means of applying low-frequency forced pressure pulses to a solid phase mixture from an external pulse-creating system. Structurally, CPE has the form of a single-body hollow column apparatus (Fig. 2) having no internal mechanical devices. The required capacity is obtained by tuning the external pulse-creating system parameters and choosing the CPE dimensions in line with the flowrate of continuously processed raw materials, physicomechanical properties of the raw materials and of the extractant and process conditions (time, temperature, pressure, etc.).

Fig.2. Internal working section of CPE

Fig.2. Internal working section of CPE

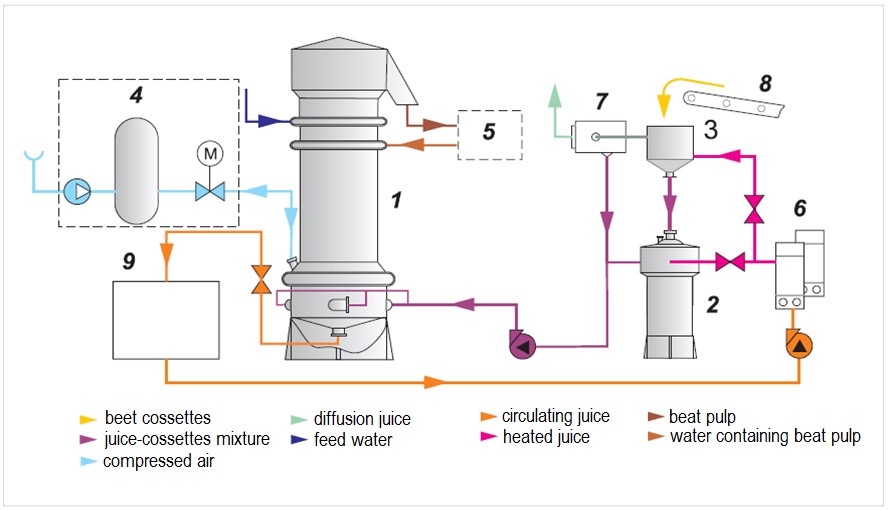

Water, ethanol, propylene glycol, acetone, alkali, acid and other active agents as well as their aqueous solutions can be used as a liquid extractant. Solid matter of various origins can be used as raw materials. For extractions from raw materials of plant origin, various parts of the plants can be used such as roots, stems, leaves, buds, inflorescences, grains, fruits or seeds in a “fresh” or dried state. Some raw materials need pretreatment such as drying, crushing, soaking, scalding, etc. Figure 3 presents an example of a technological process implementing the pulsating method of extraction (diffusion) of sugar beet with a capacity of 6000 tons/day used at sugar production. The use of CPE allows to cut significantly the energy and operating costs, metal intensity and production space, to increase the sucrose yield and improve the extract quality. Comparative characteristics of diffusion apparatus are presented in Table 1.

Fig.3. Example of a technological scheme implementing the pulsating extraction (diffusion) method for sugar production.

Fig.3. Example of a technological scheme implementing the pulsating extraction (diffusion) method for sugar production.

1 – diffusion pulsating apparatus (DPA); 2 – cossettes scalder; 3 – cossettes heater; 4 – pulse-creating system; 5 – beat press section; 6 – juice heater; 7 – beat pulp catcher; 8 – band conveyer; 9 – accumulator of juice

Table 1. Comparative characteristics of diffusion apparatus having a capacity of 6000 tons/day.

|

Parameter name |

Diffusion apparatus type |

|||

|

DPA Pulsating apparatus |

CDA Apparatus manufactured by BMA company |

RDA Rotary apparatus |

DS Screw apparatus |

|

| Aparatus type | column | column | rotary | double-screw |

| Positioning | vertical | vertical | horizontal | at inclination |

| Transportation method | by pulses | mechanical | mechanical | mechanical |

| Presence of internal transporter elements | none | hollow shaft, counter blades |

rotation of entire apparatus |

double-screw, counter blades |

| Sugar beet capacity, ton/day | 6000 | 6000 | 6000 | 6000 |

| Characteristics of beet cossettes, m/100g | 6-16 | 8-12 | 14-16 | 13-15 |

| Additional breaking of cossettes during operation | none | significant | insignificant | significant |

| Volume utilization factor | 0.93-0.98 | 0.65-0.75 | 0.3-0.4 | 0.75-0.8 |

| Zone of contact with air | none | minimum | maximum | medium |

| Diffusion time, min | 65-80 | 76-80 | 65-70 | 60-65 |

| Diameter of working zone, m | 6 | 8 | 6 | 8 – 9 (equival.) |

| Length of working zone, m | 15 | 20 | 43.5 | 35 |

|

Overall dimensions, m Height Length Width |

20 8 8 |

25 9 9 |

15 43.5 12 |

13.4 8.8 34.5 |

| Total power consumption, kW | 90 | 120 | 175 | 320 |

| Apparatus weight, ton | 180 | 300 | > 300 | >300 |

CPE is offered in various designs: airtight, with the ability to work in a closed loop; with removal of volatile components or with a mixture supplied for oxidation; with fire and explosion safety; with high degree of protection against dust and fumes. The CPE configuration, upon request from the Customer, may include additional components and equipment for preparation, supply and removal of raw materials and extractants, for cleaning and collecting the extract, for recycling and regenerating the extractant, for the instrumentation and automation system and other elements. Materials for the extractor may be ASTM A570 Gr36, ASTM A516 Gr70, AISI 304, AISI 316, etc. CPE can be supplied separately on its own support or as a part of a pulsating unit on a frame basis with the arrangement of additional external devices, service platforms and other elements.

The advantages of CPE in comparison with the existing extraction apparatus:

1. Possibility of large-tonnage processing of solid-phase raw materials with the best indicators of the economy of the technological process.

2. Continuous, countercurrent mode of extraction in non-stationary conditions of interaction of the phases provides the maximum possible yield of the target components.

3. Reduction of the extractant flowrate required for extraction to a phase ratio of 1:1 to 1:4, increasing the final concentration of the extract.

4. Improving the quality of the obtained extract by optimizing the extraction process, reducing the time of extraction, preserving the structure of the raw materials, reducing oxidative, bactericidal and other adverse processes.

5. Reduction of operating costs for extraction, for the subsequent processing of the extract (filtration, evaporation, drying, etc.), which provides increased energy efficiency, cost reduction, reduction of the required space.

6. Increased safety due to conducting extraction in a sealed apparatus and in a closed loop.

7. High competitiveness in terms of import substitution and pricing.

The implementation of breakthrough instrumental and technological solutions based on the CPE extractor will increase competitiveness and ensure a leading position in the market. For example, introduction of the CPE extractor with dimensions up to 1 m in diameter and up to 5 m in height allows for processing up to 400 kg/h of cereals and excluding from the technological process 21 apparatus (3 extraction lines with 7 percolators in each) having dimensions of 0.7 m in diameter and 4.5 m in height.

To order continuous pulsating extractors, please, provide us with the initial data and all requirement specifications through e-mail.