Experimental studies of distillation in real environments

Ingehim conducts experimental studies of distillation in real environments using our own in-house experimental units. The two units having height of 3 m represent columns of diameter 50 mm and 100 mm, respectively. The studies can be carried out either at atmospheric pressure or at vacuum and at temperatures up to 300 degrees Celcius.

Fig. 1. Experimental units for studying distillation in real environments (left unit – diameter 50 mm; right unit – diameter 100 mm)

All works are carried out by technicians having extensive hands-on experience, who are guided by engineers holding Ph.D. or D.Sc. degrees.

The Customer receives a technical report upon completion of the works.

In case you are interested, please, send us a complete description of the experiments via e-mail, so that our specialists can estimate the cost and time schedule of works.

Description of the experimental unit

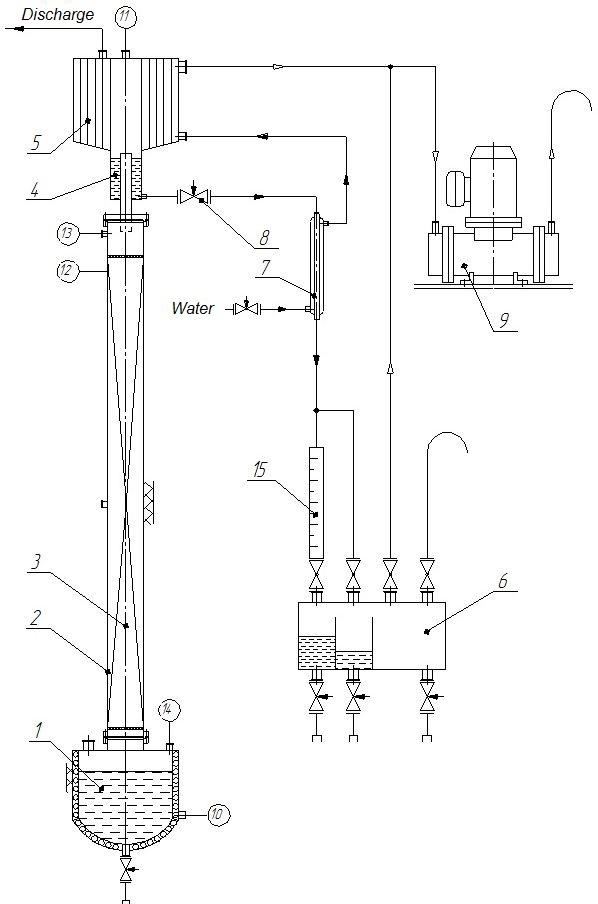

Schematic of the experimental distillation unit is depicted in Fig. 2. The unit is made up of the column’s bottom 1, distillation column 2 with packing 3, vessel of head fractions 4, helical reflux condenser 5. All the elements of the unit are made of stainless steel and mounted on the metal frame right under the ventilation hood. Extraction of distillate is carried out from vessel of head fractions 4 into receiver tank 6. The extracted distillate is preliminarily cooled in cooler 7 and the amount of extracted distillated is made adjustible by means of valve 8. Reflux condenser is loosely connected to membrane vacuum pump 9 of type НВМ-12XD, which produces vacuum pressure up to 5 mm Hg.

Fig. 2. Schematic of the experimental unit

The column’s bottom is equipped with a heating coil whose power is made adjustable to specific needs. In addition, the column’s bottom also contains a filling tube and a drain tube. As to the packing, many types of packing elements such as random packing elements of nominal size 6 fabricated by Ingehim can be utilized. On the outside, the column’s shell is equipped with an electric heater and is thermally insulated by two layers of the ceramic fibrous material called “Vladpromtex” and one layer of an aluminum foil.

Temperature at the bottom and top of the column is controlled by using thermocouples 10 and 11. The column wall temperature is determined by thermocouple 12. All the thermocouples are linked to indicators OBEH, which are connected within a single network, containing a computer, by means of the industrial interface RS-485. All the measured data are collected and processed by the SCADA system Simplight that allows investigating dynamics of the distillation process. Depth of the vacuum achieved and the pressure drop through the packed layer are controlled by vacuum meters 13 and 14. For measuring the amount of distillate collection, measuring device 15 is used.

Technical characteristics of the unit:

- Column’s internal diameter – 32 mm;

- Packed layer depth – 2 m;

- Number of theoretical plates – ~40;

- Capacity of the column’s bottom – 2 liters;

- Electric power of heating coil – 2 kW.

Advantages of the distillation unit:

- High capacity at relatively small sizes. Capable of processing up to 5 kg of feed per hour;

- Capable of separating thermally unstable compounds, which are difficult to separate by conventional methods;

- High sharpness of fractionation and low hydraulic resistance, which are achieved by using highly efficient random packing elements “Inzhekhim”;

- Capable of working at varying the reflux ratio including the case with an infinite reflux ratio ensuring the maximum fractionation of the distillation column;

- Helical reflux condenser, which ensures high heat transfer intensity and low hydraulic resistance;

- Low-inertia system of heaters, which allows to ensure the minimum run-up time;

- Automated system of experimental data collection, which allows investigating dynamics of the distillation process;

- Simple design, user friendliness and ease of use. Simple routine of experiments.

Studies on producing bitumen from very heavy crude oil

Ingehim also carries out studies on producing bitumen from very heavy crude oil for the purpose of designing pilot units. The lab-scale unit (see Fig. 3) utilizes Ingehim‘s proprietary technology (Russian patent: No.2371468). The unit successfully passed tests in the Ashalchinskoe oil field (Almetyevsk, Russia) allowing to produce unoxidized bitumen of grade BND-90/130. Quality certificate for bitumen is enclosed.

Fig.3. Experimental unit for producing unoxidized bitumen from very heavy crude oil