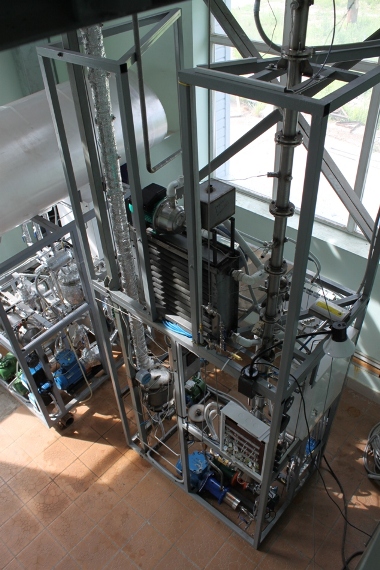

Pilot and experimental units

Ingehim designs and manufactures pilot and experimental units destined for running various chemical and heat and mass transfer processes. With the aid of the units we determine optimal process parameters of engineering devices developed in our center and also approbate novel perspective technologies developed by our center in the fields of chemistry, petrochemistry and oil refining prior to their implementation into industry. Of all pilot and experimental units developed by our center up to the present moment, the following units are of special interest:

Pilot unit for regeneration of solvents used at production of ethylene propylene rubbers

Main destination of the unit is workout of procedures for treatment of reusable solvents and monomers utilized at synthesis of ethylene-propylene rubbers. The unit can be easily altered to treat activators and modificators utilized at synthesis of different rubbers.

Experimental unit for studying alkylation processes

Experimental pulsating unit for studying hydrodynamics of the process of extraction (diffusion) from solid dispersions

Originality of the pulsating method of extraction is in the continuous technological transportation through a column-type apparatus of a solid dispersion in the form of a dense bed in the non-stationary, counterflow regime by applying low-frequency impulses of pressure (pulsations) from the external system to the liquid (extractant) without using any internal, mechanical, transporting devices (screws, augers, rotors, etc.).

Diameter of the working zone of the experimental unit is 250 mm, and the height is 1.6 m.

Ingehim develops and implements pulsating-type apparatuses for heat & mass transfer and reaction processes for the chemical, petrochemical, pharmaceutical, food and other industries.

Experimental units for studying distillation processes in the real environments

Main characteristics of columns R-100 and R-50

|

Parameter |

Units |

|

|

R-100 |

R-50 |

|

|

Column diameter |

100 mm |

50 mm |

|

Column height |

3 m |

3 m |

|

Environment |

Water-acetone, ethanol-methanol-water, etc |

Water-acetone, ethanol-methanol-water, etc |

|

Liquid load |

< 30 m3/m2h |

< 30 m3/m2h |

|

Pressure |

Atmospheric pressure, vacuum (up to 20 mm Hg) |

Atmospheric pressure, vacuum (up to 20 mm Hg) |

|

Temperature |

300 oC |

< 300 oC |

|

Measured parameters |

dp, Tt, Tb, Xt, Xb, X1 – X10 |

dp, Tt, Tb, Xt, Xb, X1 – X10 |

dp – pressure drop, Tt – temperature at column’s top, Tb – temperature at column’s bottom, Xt – product composition at column’s top, Xb – product composition at column’s bottom, X1 – X10 – product composition in 10 points along the column’s height.

Experimental unit for producing unoxidized bitumen from very heavy crude oil

Operation of the unit is based upon Ingehim‘s in-house patented technology (Russian patent: No.2371468). The unit depicted in the photograph was used to process oil from Ashalchinskoe oil field (Almetyevsk, Russia). Produced was unoxidized bitumen of grade BND-90/130. Quality certificate for the bitumen is enclosed.

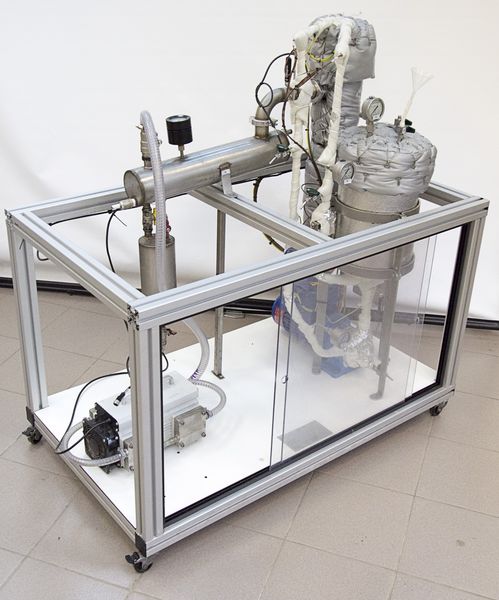

Experimental membrane unit for studying pervaporation

Ingehim offers service in designing and delivering, “on turn-key basis”, pilot and experimental units operating in the real environments destined for studying chemical and heat and mass transfer processes (distillation, absorption, desorption, adsorption, extraction, etc.).

To order our pilot or experimental units, please, provide us with all requirement specifications for the desired units through e-mail.